OUR PRODUCTS

At NValiaGroup, we offer a diverse range of high-quality polymers and additives to meet the unique needs of various industries. Our commitment to excellence extends to our product offerings, ensuring that you have access to materials that perform exceptionally. Explore our product categories below:

PP (Polypropylene)

Polypropylene is a thermoplastic material used in a wide variety of applications. Generally, it has more heat resistance and hardness than polyethylene. It also displays good chemical resistance and superior mechanical properties.

PVC (Polyvinyl Chloride)

Extremely versatile synthetic polymer, with applications in rigid and flexible forms. Used in construction, packaging, agriculture, healthcare, electrical wire and cable, and many more. PVC always requires conversion into a compound by the incorporation of additives.

LDPE (Low Density Polyethylene)

It is a thermoplastic made from the ethylene monomer, with good resistance to chemicals, acids, and alcohols, used for parts that require flexibility and softness.

LLDPE (Linear Low Density Polyethylene)

Has higher tensile strength and higher puncture resistance. It is very flexible and elongates under stress. Available in octene, hexene, butene, and metallocene-based catalysts.

HDPE (High Density Polyethylene)

HDPE is a commonly used petroleum-based thermoplastic and the most versatile type of polyethylene with a wide range of applications, including blow moulding, injection moulding, extrusion of monofilament yarns, films, pipes, and woven sacks.

PET (Polyethylene Terephthalate)

Common thermoplastic resin of the polyester family, used in fibers for clothing and bottles for storing liquids. The molecular weight of PET (Polyethylene Terephthalate) is measured by intrinsic viscosity or IV.

EVA (Ethylene Vinyl Acetate)

It is an elastomeric polymer that has flexibility and rubber-like softness. The material is used for adhesives, paints, inks, molded parts, shoe soles, and photovoltaic sheets.

ABS (Acrylonitrile Butadiene Styrene)

Provides good mechanical properties such as impact strength and toughness. It also exhibits good electrical properties. Used in either extrusion or molding applications.

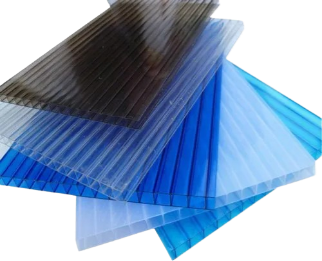

PC (Polycarbonate)

Polycarbonate is used in engineering items and is extremely tough with good impact strength. It is also optically transparent. Known for low scratch resistance, it is commonly used in eyewear lenses. Main applications are extrusion into sheets and rods and molded items such as kitchen equipment and automotive parts.

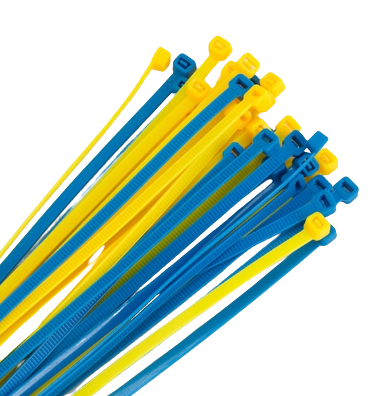

Nylon 6 (PA6)

Properties include toughness, high tensile strength, elasticity, and luster. Very resistant to chemicals. Common applications include molded parts, fibers, and filaments.

SAN (Styrene Acrylonitrile Resin)

A copolymer consisting of styrene and acrylonitrile, it offers better thermal resistance compared to polystyrene. It is optically transparent but can be brittle in behavior. Common applications include kitchenware, stationery, food containers, and battery cases.

Other Materials

- Coatings

- Tie Layer Resins

- Barrier Resins

- Waxes

- Plastomers & Elastomers

- Recycled Materials

- Off Grades & Plant Sweeping Materials

- Heat Stabilizers

- Metallic Stearates

- Plasticizers

- Technical Fabrics

- Impact Modifiers & Processing Aids